Volvo and Northvolt will open a joint research and development center in Gothenburg, Sweden. The center will be tasked with developing new batteries for EVs that deliver on range and charging time expectations while reducing the carbon footprint of the batteries themselves.

The R&D center will become operational in 2022 and the location has been chosen to keep it close to Volvo’s own R&D center as well as Northvolt‘s existing innovation campus in Västerås, Sweden, to ease cooperation.

“Our partnership with Northvolt secures the supply of high-quality, sustainably-produced batteries for the next generation of pure electric Volvos,” said Håkan Samuelsson, chief executive for Volvo Cars. “It will strengthen our core competencies and our position in the transformation to a fully electric car company.”

Read Also: BMW Signs A $2.3 Billion Battery Deal With Sweden’s Northvolt

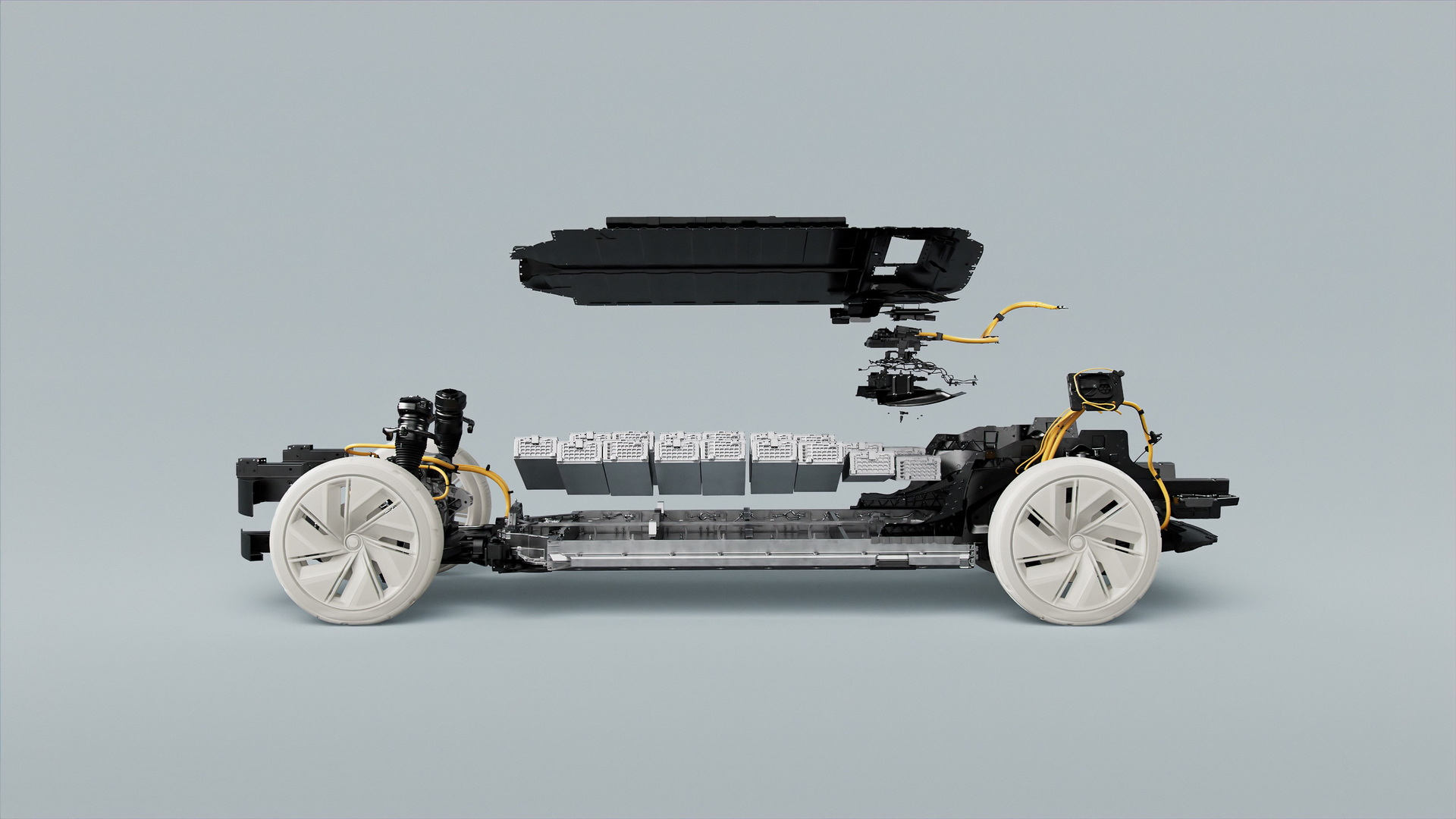

Volvo says that the partnership will focus on developing “tailor-made” batteries that give buyers long ranges and quick charging times. The automaker wants to collaborate with Northvolt to create an end-to-end system for battery manufacturing to allow it to develop its own batteries. Since batteries are the single largest component of an electric vehicle and the single biggest contributor to their carbon footprint, the development of new technology will be an important area of focus.

The center is being created as part of a SEK30 billion ($3.3 billion) investment in battery development. Batteries developed there will also power Polestar vehicles, which announced this year that it intends to build climate-neutral cars by 2030.

Following the completion of the R&D center, Volvo and Northvolt will build a battery manufacturing plant in Europe. Although the exact location of the site is not yet known, Volvo says it will be announced in early 2022.

The plant will have a potential annual capacity of 50 GWh, enough to supply about 500,000 vehicles, the automaker says. Construction is expected to commence in 2023 and large-scale production should kick off in 2026. Part of Volvo’s commitment to sell only electric vehicles by 2030, the plant and the R&D center are quite important when it comes to the automaker’s plans for the future.

For GREAT deals on a new or used Nissan check out Mossy Nissan Poway TODAY!